2021 Good Quality Grinding Glass Beads - Industrial grade hollow glass bead manufacturers – Wancheng Detail:

Product description

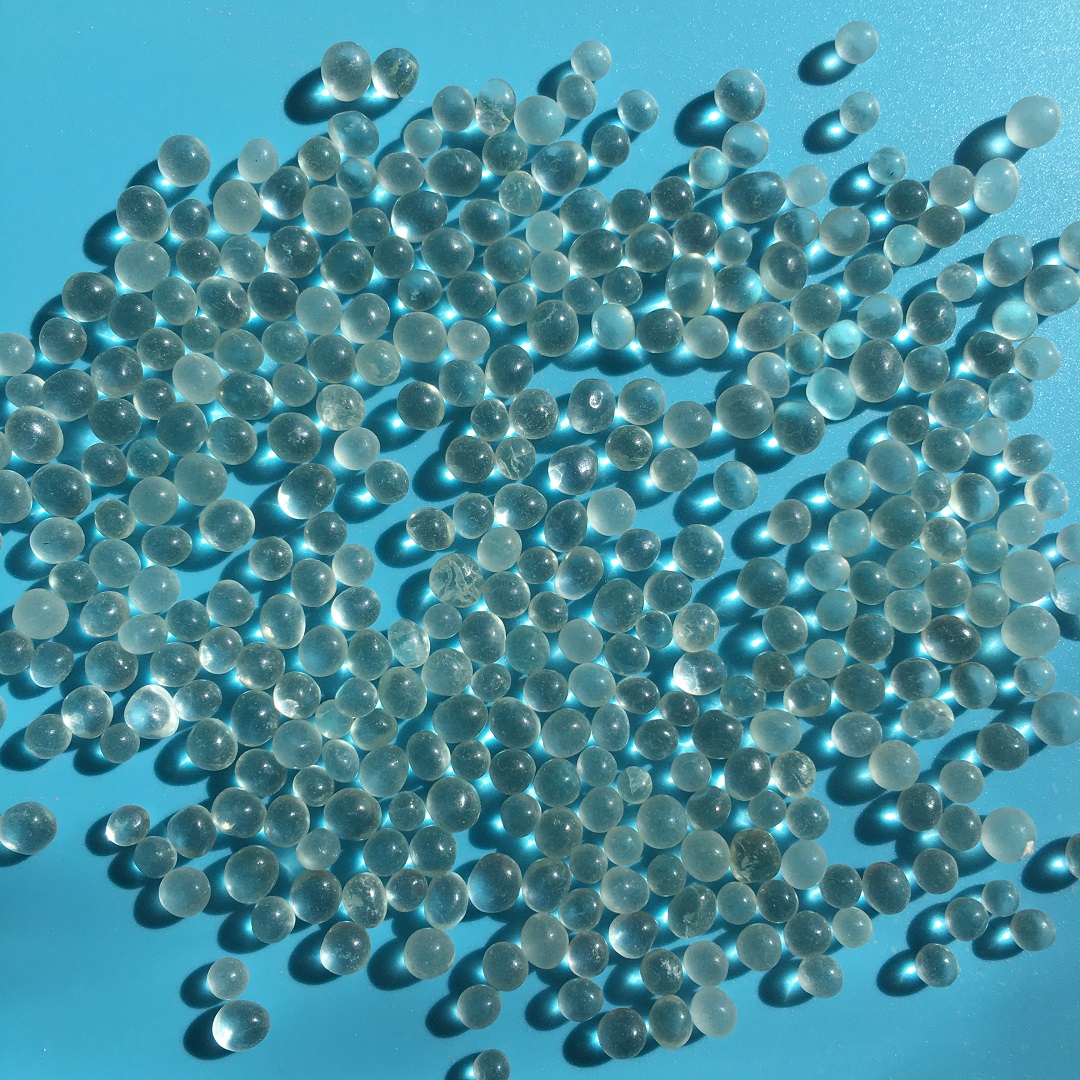

Light specific gravity and large volume. The density of hollow glass beads is about one tenth of that of traditional fillers. After filling, it can greatly reduce the base weight of products, replace and save more production resins and reduce the cost of products.

With organic modified (lipophilic) surface. Hollow glass beads can be easily wetted and dispersed, and can be filled in most thermosetting thermoplastic resins, such as polyester, epoxy resin, polyurethane, etc.

High dispersion and good liquidity. Because hollow glass beads are small round balls, they have better fluidity in liquid resin than flake, needle or irregular filler, so they have excellent mold filling performance. More importantly, this kind of small bead is isotropic, so it will not cause the disadvantage of inconsistent shrinkage in different parts due to orientation, so as to ensure the dimensional stability of the product and no warpage.

Heat insulation, sound insulation, insulation and low water absorption. The interior of hollow glass beads is thin gas, so it has the characteristics of sound insulation and heat insulation. It is an excellent filler for various heat insulation and sound insulation products. The thermal insulation characteristics of hollow glass beads can also be used to protect products from thermal shock caused by alternating changes between rapid heating and rapid cooling conditions. High resistance and low water absorption make it widely used in the processing and production of cable insulation materials.

Low oil absorption rate. The particles of the sphere determine that it has the minimum specific surface area and low oil absorption rate. In the process of use, the amount of resin can be greatly reduced. Even under the premise of high addition, the viscosity will not increase much, which greatly improves the production and operation conditions and improves the production efficiency.

Hollow glass beads are also widely used in synthetic agate, marble, FRP bowling ball and other conforming materials and high-grade thermal insulation coatings, which can significantly reduce the weight of products and have good thermal insulation effect.

Hollow glass beads are excellent sensitizers for civil emulsion explosives, which can significantly improve the initiation performance of emulsion explosives and prolong the storage period. In addition, hollow glass beads can also be used in atomic ash to increase volume, improve grinding performance and improve acid-base resistance.

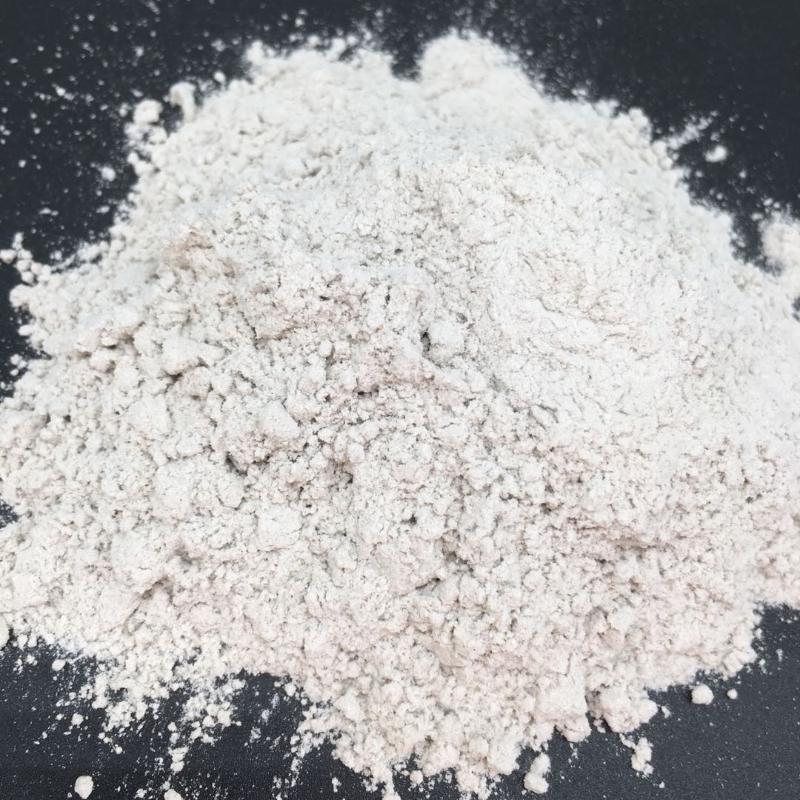

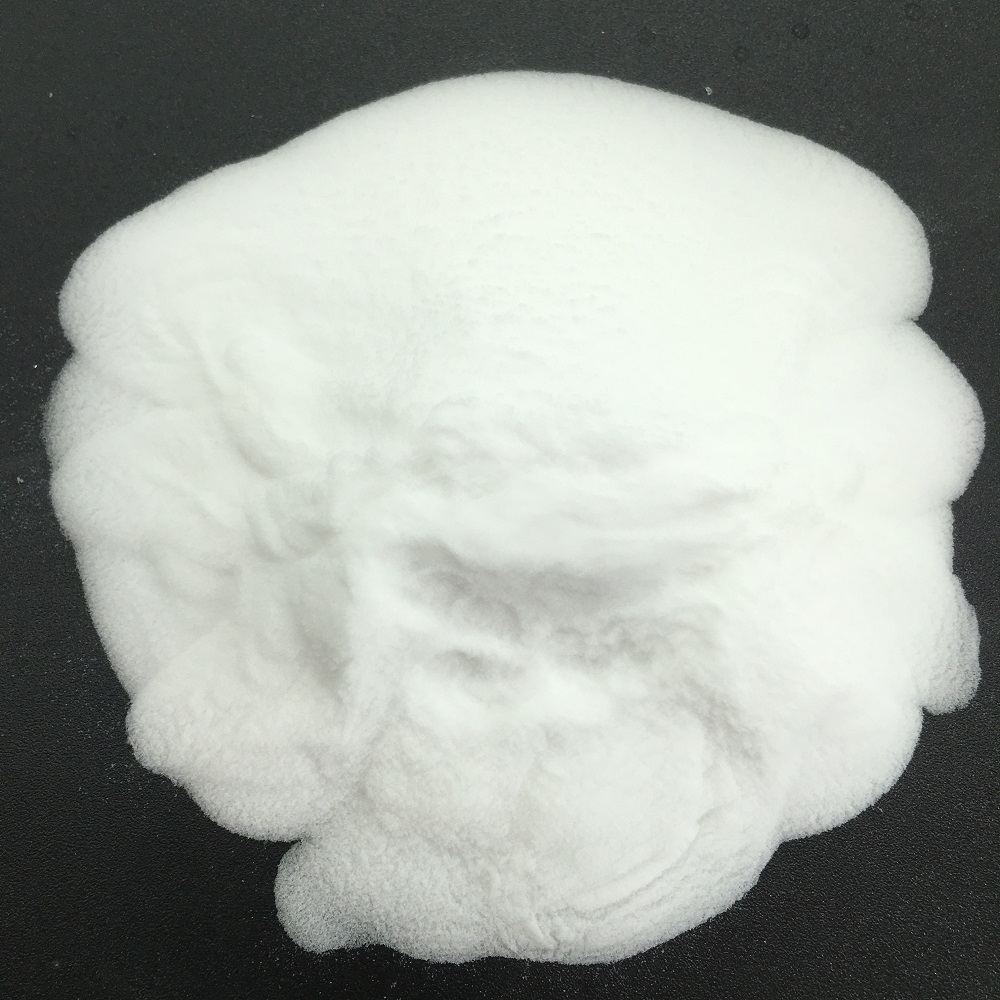

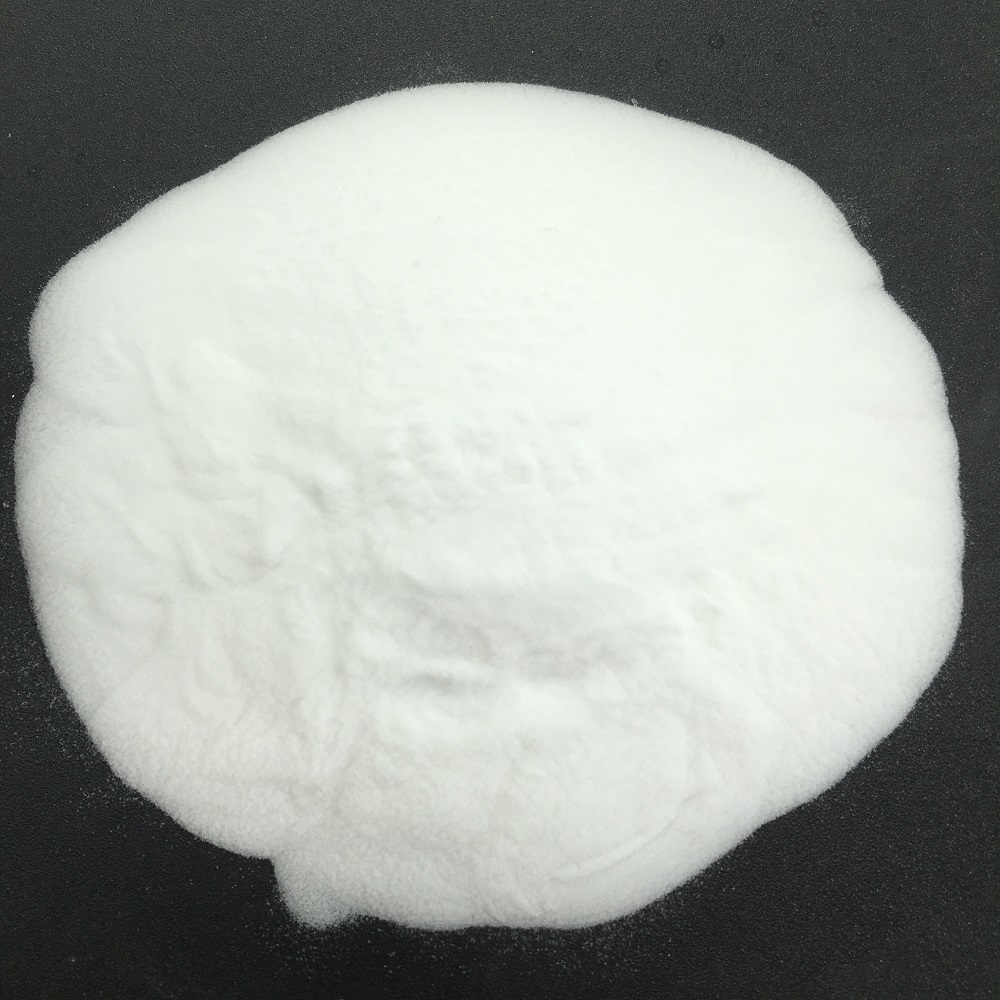

Product detail pictures:

.jpg)

Related Product Guide:

We've got a highly efficient group to deal with inquiries from shoppers. Our purpose is "100% client fulfillment by our product high-quality, price tag & our staff service" and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of 2021 Good Quality Grinding Glass Beads - Industrial grade hollow glass bead manufacturers – Wancheng , The product will supply to all over the world, such as: Swiss, Germany, America, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!