The company's synthetic mica production technology is advanced

The synthetic mica produced by Lingshou Wancheng mineral products Co., Ltd. has advanced technology, high purity, good whiteness, stable quality and reasonable price.

Synthetic mica is also called fluorophlogopite. It is made of chemical raw materials through high-temperature melting and cooling crystallization. The fraction of its single crystal chip is kmg3 (alsi3o10) F2, which belongs to monoclinic system and is a typical layered silicate. It is superior to natural mica in many properties, such as temperature resistance up to 1200 ℃. Under high temperature conditions, the volume resistivity of synthetic fluorophlogopite is 1000 times higher than that of natural mica. It has the characteristics of good electrical insulation, extremely low vacuum deflation under high temperature, acid and alkali resistance, transparency, separability and elasticity. It is an important non-metallic insulating material for modern industry and high technology such as motor, electrical appliance, electronics and aviation. More than 95% of the synthetic mica crystal blocks obtained by internal heating method are small crystals, that is, synthetic mica fragments. It can be used to make a variety of insulating products, such as synthetic mica paper, laminate, fluorophlogopite powder, mica pearlescent pigment and mica ceramics.

The observation window of water level gauge on high pressure boiler is made of traditional natural mica, which is brown, bad light transmittance and temperature range at 200-700℃, especially its weak corrosion resistance. In thermal power plant, the steam drum water in boiler contains alkali. The natural mica, after the reaction with alkali and the wash by hot water, will be easily pilling, fouling and broken. The result of which is that the water level will not be clear at the short period of time (about 1to 2months), and after being broken, it extremely easy to cause the leakage.

Synthetic mica - fluorphlogopite

Fluorphlogopite mica does not react with acid-base solution and has not hydration reaction with water, so it is not layer, not dirty and no rupture. Under the long-term scour by high temperature and high pressure water, the fluorphlogopite mica can still maintain the original transparency and clarity. Fluorphlogopite mica has been widely applied as observation window of steam drum water level gauge of high pressure boiler.

The synthetic mica sheets are suitable for a variety of uses such as substrates of thin film, windows and monochromater for x-ray, neutron diffraction, microwave and optics, spacers of electrical vacuum devices, supporters at high temperature and water-gauges of high pressure boilers, and etc., which are important in modern industry and most advanced branches of science. Fluorphlogopite mica plates are used eg. in radar technology, electron microscopes and medical equipment, aerospace and electronic components.

Apart from the use of plates made of pure fluorphlogopite, synthetic mica is used in processed form. The main product is the mica paper obtained from synthetic mica, and it, in turn, is a base for the production of micanite plates, tapes, tubes, parts etc used in temperatures up to 1100 °C.

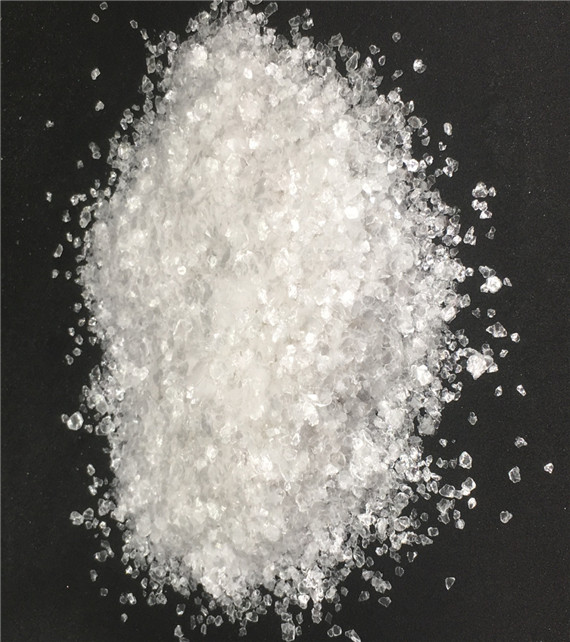

Our trade offer includes both synthetic mica in the form of plates and discs as well as ground mica of various granulation degree: from powder (grains about 5 μm) to fine flakes (about 0.4 mm).

Main specifications: + 4 mesh, - 4 mesh, 10 mesh, 20 mesh, 40 mesh, 60 mesh, 100 mesh, 200 mesh, 300 mesh, 400 mesh, 600 mesh, etc.

Post time: Apr-19-2022