-

Expanded vermiculite

Expanded vermiculite is formed by expanding the original ore vermiculite at a high temperature of 900-1000 degrees, and the expansion rate is 4-15 times. Expanded vermiculite is a layered structure with crystal water between the layers. It has a low thermal conductivity and a bulk density of 80-200kg / m3 . The expanded vermiculite with good quality can be used up to 1100C . In addition, expanded vermiculite has good electrical insulation.

Expanded vermiculite is widely used in thermal insulation materials, fire protection materials, seedlings, planting flowers, planting trees, friction materials, sealing materials, electrical insulation materials, coatings, plates, paints, rubber, refractory materials, hard water softeners, smelting, construction, shipbuilding, Chemical industry.

-

Thermal insulation vermiculite

Expanded vermiculite has the characteristics of porous, light weight and high melting point. It is most suitable for thermal insulation materials (below 1000 ℃) and fire insulation materials. After the experiment, the 15 cm thick cement vermiculite plate was burned at 1000 ℃ for 4-5 hours, and the back temperature was only about 40 ℃. The seven centimeter thick vermiculite plate is burned for five minutes at a high temperature of 3000 ℃ through fire welding flame net. The front side melts, and the back side is still not hot with hands. So it exceeds all insulation materials. Such as asbestos, diatomite products, etc.

-

Fireproof vermiculite

Fireproof vermiculite is a kind of natural and green environmental protection fireproof material. It is widely used in fireproof doors, fireproof ceilings, floors, vermiculite concrete, horticulture, fishery, shipbuilding, industry and other fields with mature technology. In China, the application fields of fireproof vermiculite are more and more, and its development prospect is very broad.

-

Incubate vermiculite

Vermiculite is used to hatch eggs, especially reptile eggs. The eggs of various reptiles, including geckos, snakes, lizards and turtles, can be hatched in expanded vermiculite, which must be wetted in most cases to maintain humidity. Then a depression is formed in vermiculite, which is large enough to place reptile eggs and ensure that each egg has enough space to hatch.

-

Vermiculitse Board

Vermiculite board is a new type of inorganic material, which uses expanded vermiculite as the main raw material, is mixed with a certain proportion of inorganic binder, and is processed through a series of processes. It has high temperature resistance, fire protection, green environmental protection, heat insulation, sound insulation, Plates containing harmful substances. Non-combustible, non-melting, and high temperature resistant. Because vermiculite board uses expanded vermiculite as the main raw material, inorganic materials have no carbon element and do not burn. Its melting point is 1370 ~ 1400 ℃ , the maximum operating temperature is 1200 ℃ .

-

Filled glass beads

Filled glass beads is a new type of material with wide application and special properties developed in recent years. The product is made of borosilicate raw materials through high-tech processing, with uniform particle size of small glass beads. Chemical composition: SiO2 > 67%, Cao > 8.0%, MgO > 2.5%, Na2O < 14%, Al2O3 0.5-2.0, Fe2O3 > 0.15 and other 2.0%; Specific gravity: 2.4-2.6 g / cm3; Appearance: smooth, round, transparent glass without impurities; Rounding rate: ≥ 85%; Magnetic particles shall not exceed 0.1% of the product weight; The content of bubbles in glass beads is less than 10%; It does not contain any silicone components.

-

Grinding Glass Beads

Ground glass beads, appearance: colorless transparent sphere, smooth and round, without obvious bubbles or impurities.

Rounding rate: rounding rate ≥ 80%;

Density: 2.4-2.6g/cm3;

Refractive index: Nd ≥ 1.50;

Composition: sodium calcium glass, SiO2 content > 68%;

Compressive strength: > 1200n;

Mohs hardness: 6-7. -

Colored glass beads

The name of colored glass beads is thought to be colorful glass beads. This kind of colored glass beads is formed by adding some various pigments in the early stage of glass bead production to make it evenly distributed in each part of each glass bead. Colored glass beads are bright, full and durable. This kind of glass beads is resistant to wind and sun, and will not fade or deform. This kind of colored glass beads can be used in road marking, building exterior wall decoration, garden decoration, clothing, jewelry and other fields. Colored glass beads have uniform particle size, round particles, rich and colorful colors and beautiful colors. It has good compatibility with various resins and has the characteristics of good color fastness, acid resistance, chemical solvent resistance, heat resistance and low oil absorption. It is also widely used in architectural decoration, Caulking agent, children’s toys, handicrafts, lighting and other products.

-

Hollow glass beads

Hollow glass bead is a kind of hollow glass sphere with small size, which belongs to inorganic non-metallic material. The typical particle size range is 10-180 microns, and the bulk density is 0.1-0.25 g / cm3. It has the advantages of light weight, low thermal conductivity, sound insulation, high dispersion, good electrical insulation and thermal stability. It is a new lightweight material with wide application and excellent performance developed in recent years. The color is pure white. It can be widely used in any product with requirements for appearance and color.

-

Composite rock slice

The color composite rock slice is made of polymer resin, inorganic raw materials, chemical additives and other raw materials through special processes. It is mainly applied to the colored imitation granite stone paint on the interior and exterior walls of high-grade buildings to replace the granite dry hanging on the exterior walls of high-grade buildings.

-

Dyed colored sand

Artificial colored sand is made by dyeing quartz sand, marble, granite and glass sand with advanced dyeing technology. It makes up for the shortcomings of natural colored sand, such as low color and few color varieties. Varieties include white sand, black sand, red sand, yellow sand, blue sand, green sand, cyan sand, gray sand, purple sand, orange sand, pink sand, brown sand, round sand, real stone paint color sand, floor color sand, toy color sand, plastic color sand, colored pebbles, etc.

-

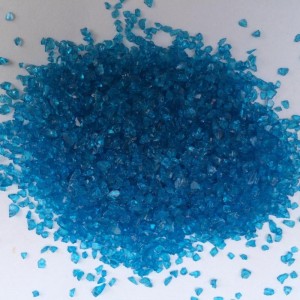

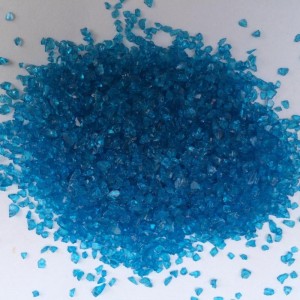

Glass sand

Colored glass sand is made by color treatment of glass sand with advanced dyeing technology. Its varieties include: white glass sand, black glass sand, red glass sand, yellow glass sand, blue glass sand, green glass sand, cyan glass sand, gray glass sand, purple glass sand, orange glass sand, pink glass sand and brown glass sand

Common specifications: 4-6 mesh, 6-10 mesh, 10-20 mesh, 20-40 mesh, 40-80 mesh, 80-120 mesh, etc.